3D-printed moulds facilitate making an anatomically matched cement spacer for reconstruction long bone defection after resection of tumors of humerous

DOI:

https://doi.org/10.3126/njc.v2i1.25647Keywords:

3D-print, Anatomical cement spacer, Proximal humerus, OsteosarcomaAbstract

Background: A nail and cement spacer is one of the option for the reconstruction of the proximal humerus after tumor resection among prosthesis unaffordable patients. However, making the cement spacer anatomically match its replacement remains challenging.

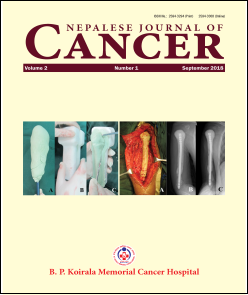

Presentation of case: A 12-year-old boy was diagnosed with osteosarcoma in the right proximal humerus by core needle biopsy. After preoperative neo-adjuvant chemotherapy, a wide resection was performed, and the defect was reconstructed with an anatomically matched cement spacer. The cement spacer was fabricated using 3D-printed moulds, which were made according to the mirror image of the left humerus based on CT data. The post-operative course was uneventful, and at the 12-month follow-up, the patient is able to move with only some restriction in abduction and upward lift. The MSTD score was 21.

Conclusion: Fabrication of an anatomically matched cement spacer using 3D-printed moulds is a simple, inexpensive, and reproducible procedure for reconstruction complex bone defect.

Downloads

Downloads

Published

How to Cite

Issue

Section

License

This license lets others distribute, remix, tweak, and build upon your work, even commercially, as long as NJC and the authors are acknowledged.

Submission of the manuscript means that the authors agree to assign exclusive copyright to NJC. The aim of NJC is to increase the visibility and ease of use of open access scientific and scholarly articles thereby promoting their increased usage and impact.